Manufacturing Automation Consulting

Automation Engineering Consulting Services - Camus, WA

Let's optimize your manufacturing operations with automation that's smart, seamless, and straightforward.

- Aerospace

- Ag Tech

- Automation

- Manufacturing Automation Consulting

- Consumer Products

- Defense

- Health & Wellness

- Industrial Equipment

- Semiconductor

- Uncrewed Systems

- Aerospace

- Ag Tech

- Automation

- Manufacturing Automation Consulting

- Consumer Products

- Defense

- Health & Wellness

- Industrial Equipment

- Semiconductor

- Uncrewed Systems

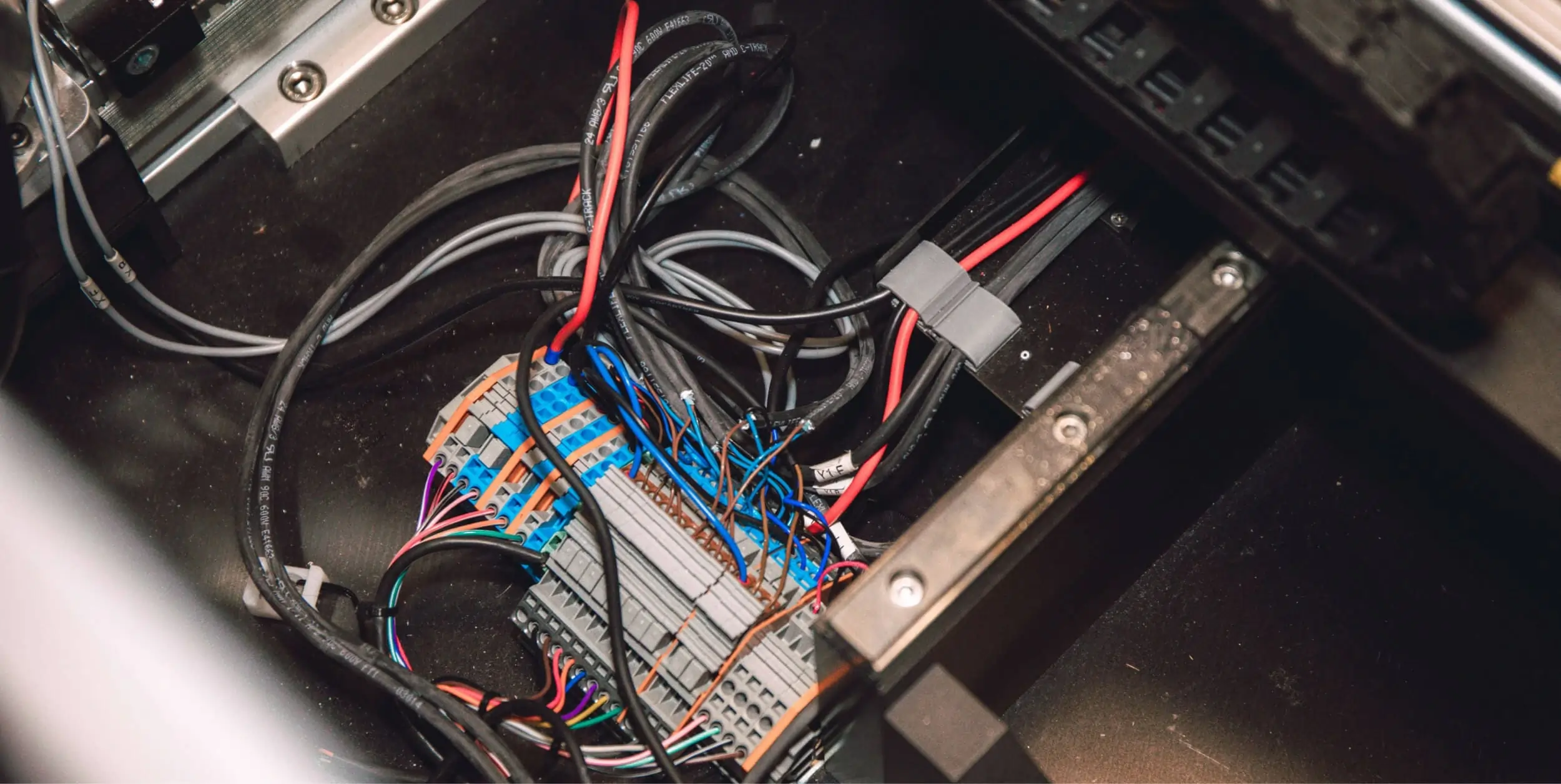

At Sigma Design, we're all about empowering your manufacturing operations with automation that's smart, seamless, and straightforward. Whether it's introducing automation to a small part of your production line or revolutionizing your entire manufacturing process, we're here to guide you every step of the way.

Our expertise is in crafting manufacturing automation solutions that align with your unique operational needs. Right from the start, we delve into the specifics of your manufacturing processes, applying our comprehensive skills in design, engineering, and prototyping to ensure that our solutions are not just innovative but also practical and effective.

Expert Collaboration

You have the support of a team of experts ready to help get your line operating efficiently and successfully.

Complete Automation Lifecycle Support

From initial planning to final execution, Sigma Design covers every phase of automation integration.

Adaptive and Scalable Solutions

Our automation strategies are flexible, catering to both small and large-scale manufacturing needs.

Our goal? To enhance your manufacturing efficiency, productivity, and adaptability in the face of evolving market demands.

With Sigma Design, you're choosing a partner dedicated to your success and driven by the desire to help you achieve tangible, impactful results. Let's work together to transform your production line into a model of automation success.