Defense-Grade Mechanical Engineering

Our aim is to ensure mission-critical systems perform reliably under extreme conditions.

We are an ITAR Registered manufacturer, ISO-9001:2015 QMS, ISO-27001:2013 Information Security, and JCP Certified organization.

Your Team Partner for Military-Grade Solutions

Types of Work We Do for our Defense Clients

- Blast-resistant and ballistic protection systems

- Thermal management for high-energy defense technology

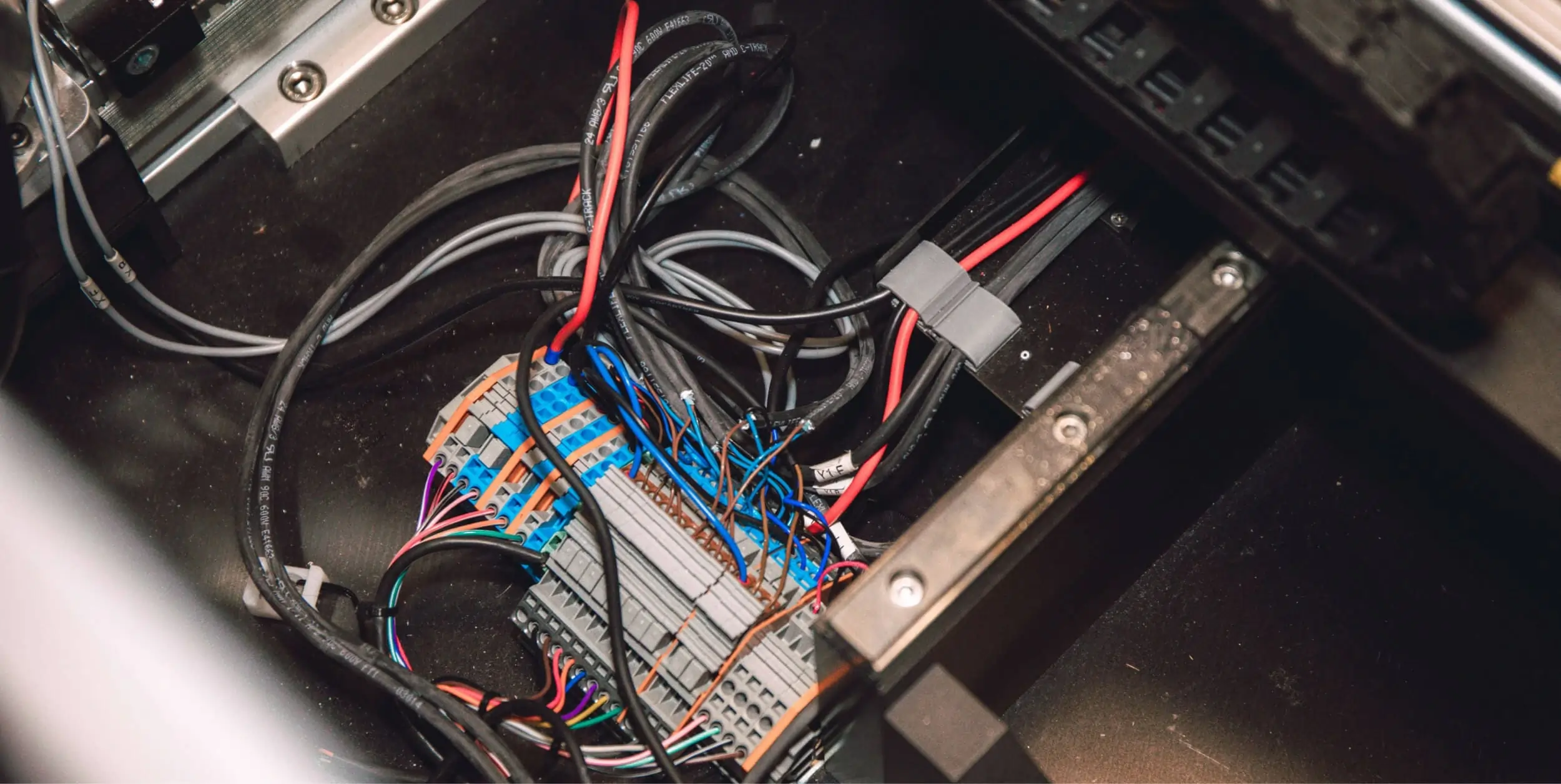

- Waterproof and EMI-shielded enclosures

- Precision mechanical assemblies for military applications

- Custom-designed battery enclosures for defense electronics

Core Mechanical Engineering Capabilities for Defense

- Structural & Thermal Analysis – Using finite element analysis (FEA) and computational fluid dynamics (CFD) (Learn more), we optimize for stress, vibration, and heat dissipation to ensure robust and durable designs.

- Prototyping & Testing – Our expertise in 3D CAD modeling, small- and large-scale prototyping, and rigorous testing accelerates development while ensuring compliance with defense performance standards.

- Materials & Manufacturing Engineering – We conduct high-performance material evaluations (Materials Testing) and apply Design for Manufacturability (DFM – you can read our tips) to enhance strength, weight efficiency, and cost-effectiveness.

- Failure Analysis & Lifecycle Optimization – We perform durability assessments, failure mode analysis, and lifecycle optimization to extend the performance of mission-critical defense systems.

Mechanical Solutions for Defense Applications

- MIL-STD Compliance – We design and test components to meet MIL-STD-810 (environmental conditions) and MIL-STD-461 (EMI/EMC compliance).

- Ballistic & Blast Protection – Our mechanical designs integrate structural reinforcements and impact-resistant materials for maximum protection.

- Sealing & Environmental Protection – We develop enclosures and components that withstand extreme temperatures, water exposure, and chemical exposure.

- Shock & Vibration Mitigation – Our expertise ensures that defense systems maintain structural integrity and performance under high-impact conditions.

Certifications & Compliance

- ITAR-Registered – Ensuring compliance with U.S. defense regulations.

- ISO 9001:2015 QMS Certified – Committed to high-quality manufacturing and engineering standards.

- Cybersecurity Compliant – Meeting CMMC and NIST 800-171 security protocols for defense technology.

Partner with Sigma Design for Advanced Defense Mechanical Engineering

At Sigma Design, we combine engineering expertise, precision, and compliance to develop innovative mechanical solutions for defense applications. From design to analysis to advanced prototyping, our team ensures your mission-critical systems perform at the highest level.

Let’s collaborate on your next defense challenge.

FAQs Mechanical Engineering for Defense

Can Sigma place a team on-site at our facility?

What types of mechanical engineering solutions does Sigma Design create for defense applications?

How does working with an ITAR registered mechanical engineering firm differ from standard engineering companies?

Why do defense contractors choose Sigma Design for complex mechanical engineering projects?

How can Sigma Design help when defense mechanical projects face delays due to resource constraints?

What makes Sigma Design different from general mechanical engineering firms working on defense projects?

How does Sigma Design ensure mechanical designs meet military standards and specifications?

Do you use specific tools when designing for the defense industry?

Find out how we can securely integrate, design, create, and solve for your unique challenges.