Testing for Defense Systems

We are an ITAR Registered, ISO-9001:2015 QMS, ISO-27001:2022 Information Security, and JCP Certified organization, and our capabilities span the entire product lifecycle from design and development to testing and manufacturing.

Precision Testing for Mission-Critical Defense Systems

Sigma Design provides customized testing solutions that ensure mission-critical defense systems meet stringent military and aerospace standards. We have the ability to collaborate with major defense contractors. Our tailored test plans validate durability, environmental resilience, and system performance under extreme conditions—providing confidence that your technology is mission-ready.

Custom Test Plans for Defense Applications

Often times off-the-shelf testing isn't enough because no two defense projects are the same. That's why Sigma Design develops custom test plans to align with specific defense standards, including:

- Requirement Analysis – Defining critical performance metrics and operational conditions.

- Tailored Testing Protocols – Executing MIL-STD and industry-compliant procedures.

- Risk-Based Testing – Identifying high-risk failure modes in mission-critical systems.

- Iterative Testing & Design Feedback – Refining designs based on real test data.

- Compliance & Documentation – Providing detailed reports to meet regulatory requirements.

Our expertise enhances reliability, streamlines production, and reduces failure rates.

Defense Testing Capabilities

Sigma Design’s A2LA-accredited test lab (ISO/IEC 17025:2017) has provided services for defense contractors testing products for the Army, Navy, Air Force, and Space Force. We conduct:

- MIL-STD-810 G & H Testing – Verifying performance under extreme temperature, humidity, and shock conditions.

- MIL-STD 202 G & H Testing – Determining environmental, physical, and electrical tests for electronic and electrical component parts.

- Vibration & Shock Testing – Ensuring components maintain structural integrity under impact and operational stress.

- Ingress Protection (IP) Testing – Testing resistance to water, dust, and electromagnetic interference (EMI).

- Accelerated Lifecycle Testing – Simulating long-term use to identify failure points before deployment.

- Mission-Specific Load Testing – Assessing mechanical and electronic components under real-world operational loads.

- System Integration Testing – Verifying seamless compatibility in complex defense architectures.

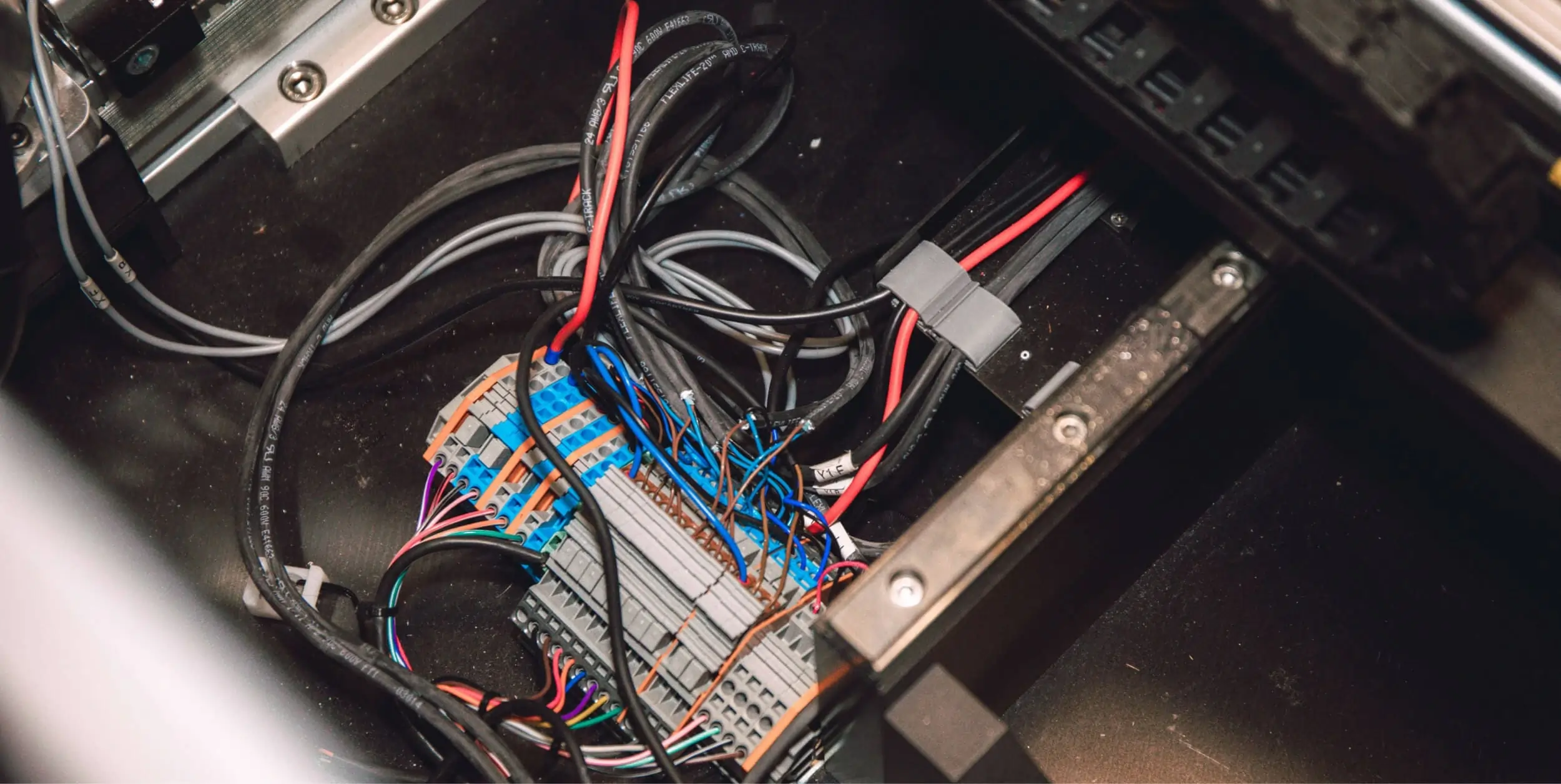

Advanced Instrumentation & Analysis

Sigma Design employs high-precision instrumentation and advanced data acquisition to capture critical performance data.

Key Capabilities

- Temperature & Strain Measurement

- High-Speed Data Acquisition (Hundreds of Channels)

- Thermal Imaging & Pressure Sensors

- Computational Fluid Dynamics (CFD) Simulation

- Finite Element Analysis (FEA) Validation

- Failure Mode & Effects Analysis (FMEA)

Compliance & Certifications

- ISO/IEC 17025:2017 Accredited (Mechanical) – Certificate Number: 6427.01

- ISO 9001:2015 QMS Certified – Meeting stringent quality standards.

- MIL-STD Testing Expertise – Ensuring military-grade reliability.

- Cybersecurity Compliant – Adhering to CMMC protocols.

- ITAR-Registered – Compliant with U.S. defense export regulations. This includes:

- Access Controls

- Technical Data Protection

- Foreign National Screening

- Deemed Export Compliance

- Detailed Documentation & Record Keeping

- Regular Employee Training

FAQs Testing for Defense

What is defense engineering testing and why is it important for military projects?

What makes Sigma Design uniquely qualified for sensitive military technology testing?

What types of iterative testing does Sigma Design offer for defense technology?

How does Sigma Design maintain confidentiality throughout the defense testing process?

How does Sigma Design ensure security compliance for government defense projects?

How does working with an ITAR registered company differ from standard engineering firms?

Why do government agencies choose Sigma Design for defense engineering projects?

How can Sigma Design help when defense projects get stuck due to resource constraints?

Why Sigma Design?

At Sigma Design, we recognize that successful defense testing goes beyond standard procedures—it requires a strategic, mission-driven approach that aligns with specific needs. Testing is crucial to mission-critical products to verify it will behave as expected and meet military and aerospace standards.

Sigma Design develops methods of test suited to your specific product and requirements. With experienced engineers, machinists and technicians all in-house, we can provide custom test fixtures and tailored test programs. We are ready to partner with you to test your product!