Prototyping is the process of creating an early sample, model, or release of a product to test and validate design concepts, functionality, and user experience. It bridges the gap between an idea and a final product, enabling designers and engineers to explore improvements, gather feedback, and verify feasibility before production.

How We Handle Prototyping Sigma Design provides comprehensive, rapid-prototyping integrated with full fabrication and engineering services. To be clear, we are not a “rapid-prototyping” house, but we do have a full shop that fabricates and machines individual parts or depending on the needs of our customers.

Let’s be clear, prototyping and prototype manufacturing are related but not the same:

- Prototyping focuses on designing and building early versions of a product to test form, function, and feasibility. It’s iterative, often experimental, and aims to validate design concepts. Sigma Design helps many customers in this stage.

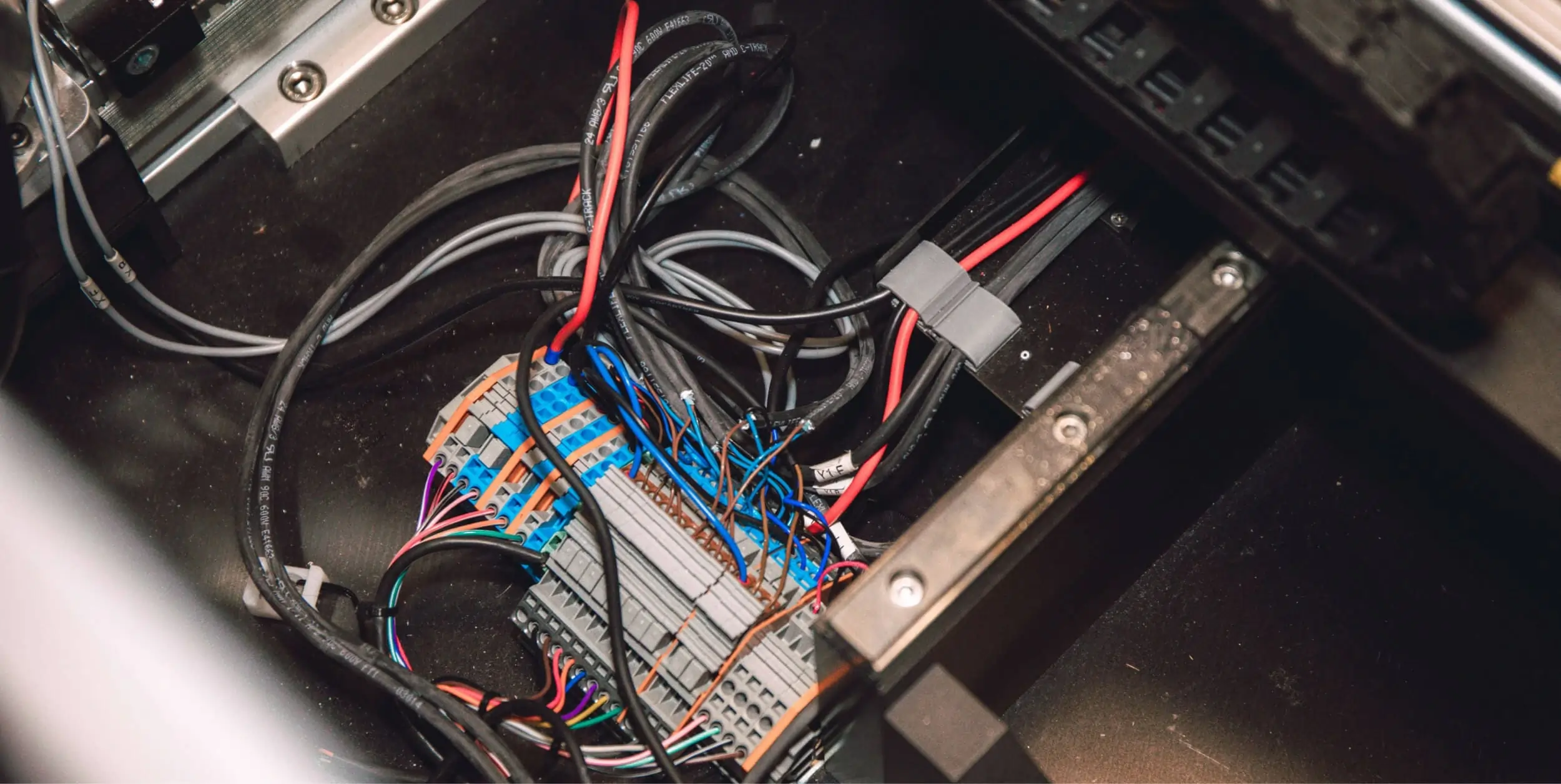

- Prototype manufacturing refers specifically to the production process used to build those prototypes. It involves manufacturing methods (such as fabrication and machining process) to create one-off or limited-run parts with production-level precision. Our team is adept at this, and we have a variety of team members with the right expertise to provide the execution of building working prototypes.

Sigma Design offers both prototyping and prototype manufacturing under one roof. With integrated design and build functions in-house we streamline the transition from concept to testable products.