POC Food Wrap Printer

Sigma Design developed a Proof of Concept for a food wrap printer that would print custom graphics on a sandwich wrapper on-demand on location, per customer’s order. Sigma Design developed a prototype unit by customizing an existing hardware product and creating custom software and apps to create and print custom information.

Problem Statement

The customer was trying to drive the idea internally within their company, so we helped them to provide a functional prototype to demonstrate the capabilities to their internal teams.

Solution

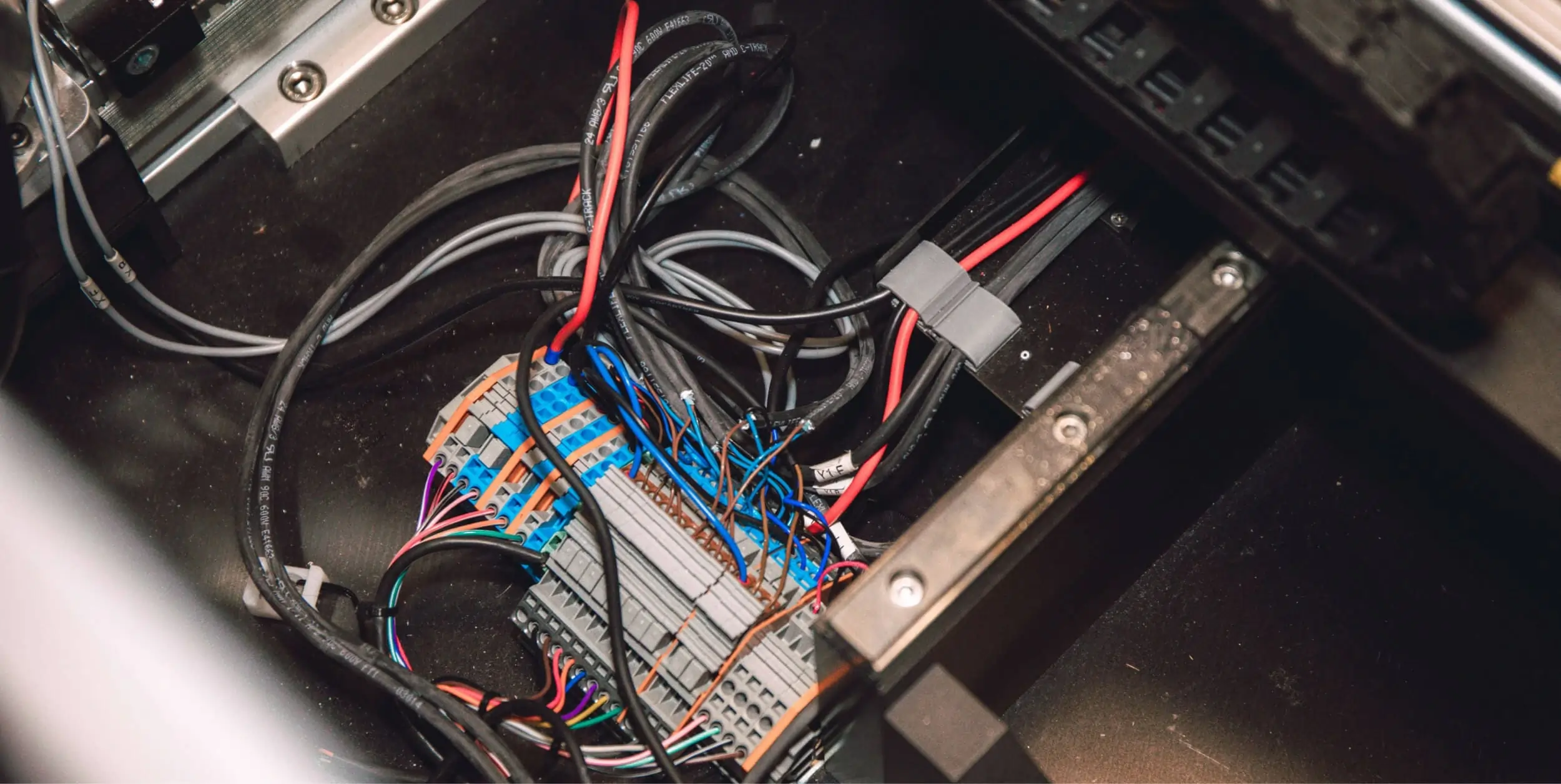

We took an existing printing platform and added a custom paper path to allow the printer to print to existing rolls of sandwich paper. We also added a custom knife to cut the sandwich paper to length. We then created software to run both on the hardware (to control the knife and paper path motors) and on a PC to send prints to the printer. To get it all to function properly, we had to “trick” the printer into thinking it was printing normally by adding dummy sensors or signals. We then created an app to customize the custom information to be printed and used it to send and print the custom wrapper.

We started out with an off-the-shelf printer and needed to figure out how to get it to print to a custom paper path without knowing it. We started out by disabling sensors or motors and seeing how the printer responded to the change. In the end we ended up needing to leave motors attached and faking out a few other sensors that had to do with paper placement and alignment, since there wasn’t paper traveling through the system.

Once we figured out how to mechanically “fake-out” the printer, it was a matter of developing a custom paper path that included rollers for moving the paper, an idler to keep tension on the paper since it was coming off a roll, a cutter for cutting the paper to dynamic lengths, and a “chute” for the paper to be delivered to the operator in a fashion that allowed them to easily grab the paper off the top of the stack and gave enough time for the ink to dry on the page.

App and Software

- To facilitate a seamless user experience, a custom app was developed in-house that demonstrated the ability to easily order custom sandwiches (in this example, sandwiches from Arby’s) with custom ingredients then print them to the printer over WiFi with the click of a button.

-

Custom .NET software running on a SBC (Small-board computer) was embedded into the printer which was used to receive the data (orders) coming from the app, process that data into an image, and then print those generated images onto the wrapper. The software handled the TCP communication to the APP using a TCP server, communication with the printer using standard printing drivers, and sending high-level commands to an embedded Galil controller which handled the paper path motors and the cutter using concurrent motion profiles.