NPI Manufacturing

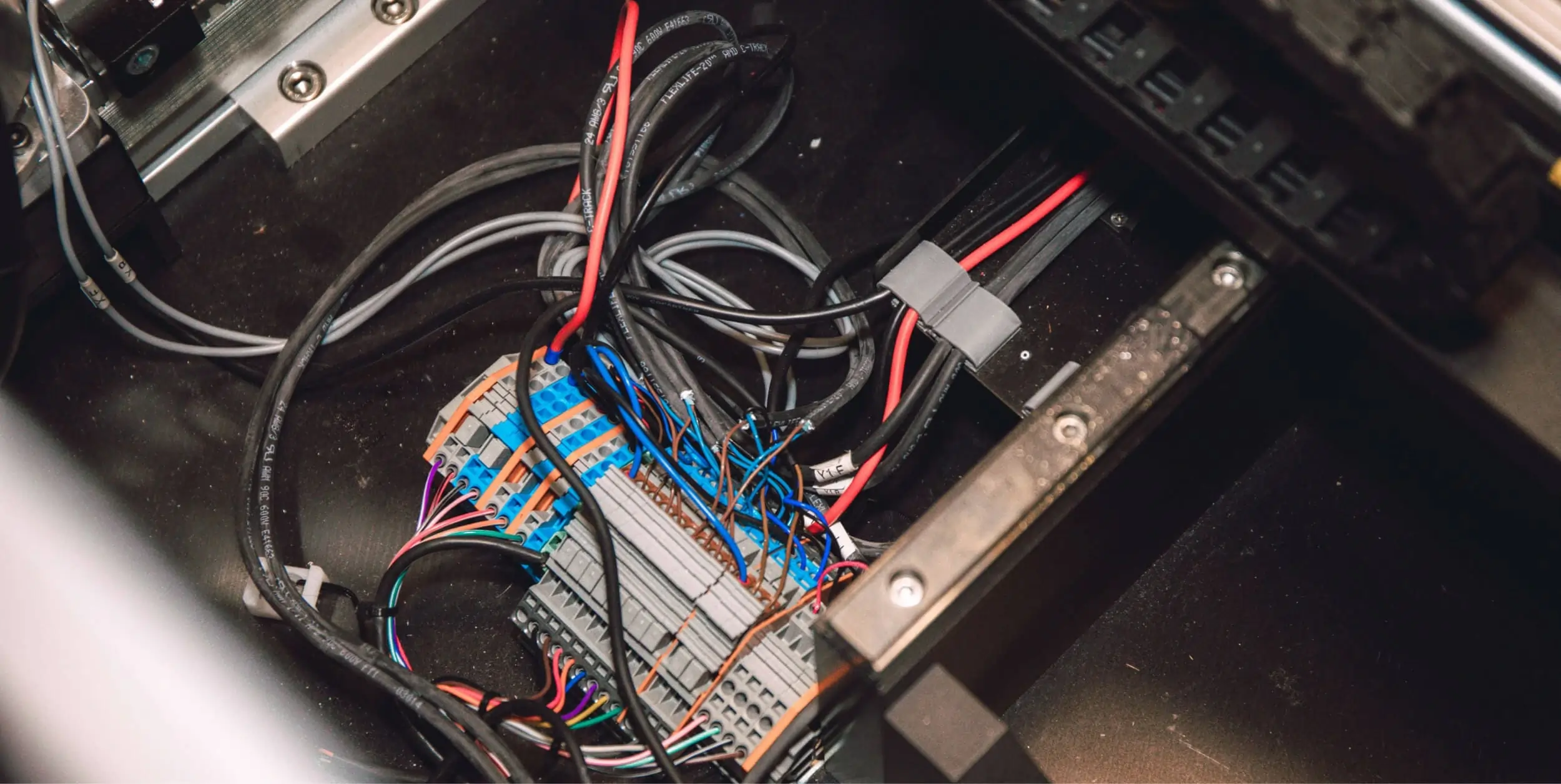

Our NPI Manufacturing process takes your new product from prototype to production.

We work closely with you to plan smart, build right, and get your product to market smoothly and reliably.

At Sigma Design, NPI Manufacturing (New Product Introduction Manufacturing) refers to the process of taking a new product from prototype to production, ensuring it’s ready for market launch with quality, efficiency, and scalability.

Our NPI manufacturing process includes comprehensive DFM analysis to optimize your product for efficiencies and cost reduction, thorough production readiness assessments, rigorous quality assurance, time-to-market acceleration, and supply chain optimization.

Key Aspects of NPI

Key aspects of NPI Manufacturing at Sigma Design include:

- Cross-functional collaboration. Engineering, manufacturing, and supply chain teams work closely to transition designs into manufacturable products.

- Design for Manufacturability (DFM). Early-stage reviews optimize the product for cost-effective, reliable production.

- Prototyping and Validation. Functional and pre-production builds are tested to verify design intent and manufacturability.

- Process Development. We create and refine assembly processes, work instructions, and quality plans tailored to the product.

- Scalable Production. NPI efforts lay the foundation for full-scale manufacturing, whether in-house or at another contract manufacturer.

Our NPI Expertise

Sigma Design's New Product Introduction capabilities serve a diverse range of industries, from cutting-edge aerospace and defense applications to innovative consumer products and wearable technology. Our comprehensive NPI process supports clients across agricultural technology, automation systems, health and wellness devices, industrial equipment, semiconductor manufacturing, and uncrewed systems as they transition from prototype to full production. Whether you're launching specialized components for aerospace applications, custom automation solutions, breakthrough medical devices, or next-generation consumer electronics, our integrated approach ensures smooth product launches while mitigating risks and optimizing manufacturability. With our in-house design and engineering team working directly alongside our manufacturing specialists, we provide seamless collaboration throughout the entire NPI process—from design for manufacturability reviews and pilot production runs to supply chain establishment and process validation—ensuring your new products reach market faster with consistent quality and optimized production efficiency across these demanding industries.

NPI Manufacturing FAQs

Can custom manufacturers handle both prototypes and production?

Partner With Us

NPI Manufacturing at Sigma Design bridges innovation and execution. We help our customers move confidently from concept to product by manufacturing solutions and success.

Through cross-functional collaboration, design optimization, rigorous validation, and scalable production planning, we ensure your product is market-ready with speed, quality, and reliability.

Ready to launch? Let’s build your next success together.