Product Testing Services

Product Testing and Compliance Services

Rigorous testing and quality assurance to ensure your products meet and exceed quality and compliance requirements.

- Test

- Material Testing

- Product Testing

- Software Quality Assurance

- Testing Services

- Test

- Material Testing

- Product Testing

- Software Quality Assurance

- Testing Services

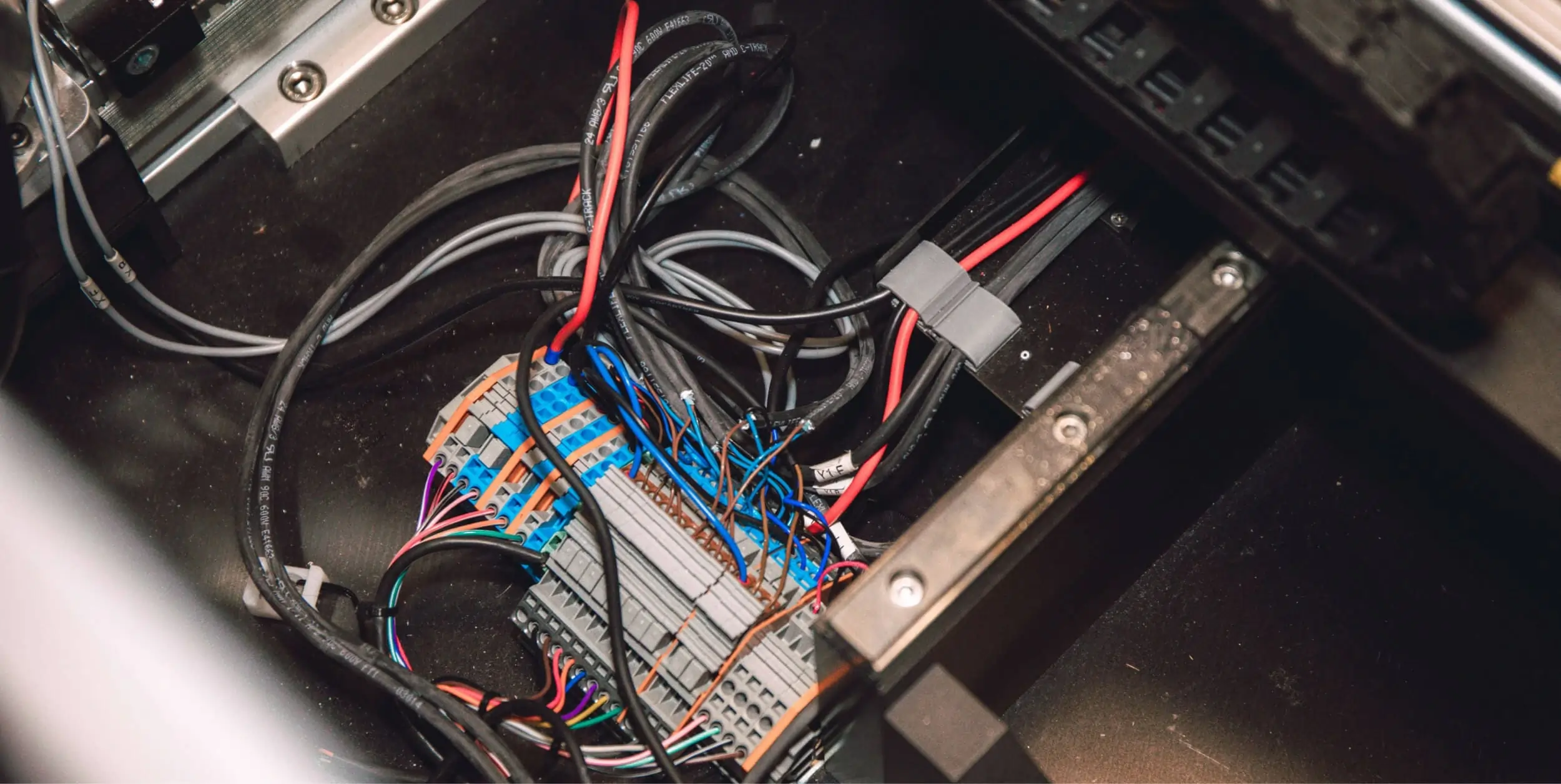

Our dedicated Test Lab provides a broad range of testing services for both the product development process and for standards compliance. During the product development process, test results and failure analysis yield product improvements and cost/performance optimization.

As your product nears the market, we assure you that it will meet appropriate standards. These standards range from MIL-STD protocols to ANSI/ASTM/ISO/IEC standards. We also test to industry-specific standards such as SEMI or ISTA, or your unique, internal standards.

We're passionate about getting things just right, which means we put every innovation through some serious quality checks. It's all about making sure everything we do not only hits the mark but does so with flying colors.

By diving deep into analysis and simulations, we're always on the lookout for ways to tweak and improve. It's this careful attention to detail that reassures our clients and partners they're in good hands.

Our goal is to build trust through dependable and forward-thinking solutions. This commitment to excellence is what helps us deliver results that not only last but also help us lead the way in our field. It's about striving for the best, not just for the sake of perfection, but to genuinely make a difference.

Sigma Design is accredited ISO/IEC 17025:2017 for Testing/Calibration Laboratories from the assessment accreditation services body American Association for Laboratory Accreditation (A2LA). Sigma Design hold the certificate #6427.01 specifically for the Mechanical Field of Testing.

Our ISO/IEC 17025:2017 for Testing/Calibration Laboratories accreditation is important to industries with high-risk factors associated such as aerospace, medical and defense. This designation is a significant because Sigma Design is 1 of only 2 accredited test labs in the Portland, Oregon metro area for general industry mechanical testing.