Accufit Digital Measurement System

The AccuFit System, developed for LensCrafters, was the first digital measurement system in the US and Canada.

The AccuFit System, developed for LensCrafters, was the first digital measurement system in the US and Canada. The primary technology behind the system involved custom software and IT integration, but the delivery system was equally important.

Sigma Design collaborated with Ziba Design to ensure that the transition to manufacturing was as seamless as possible. Sigma Design representatives traveled to LensCrafters headquarters in Mason, Ohio to meet with LensCrafters’ executive team responsible for the deployment effort. Because these units were being installed in retail stores and just a few feet from the consumer, pristine, consistent and quality fabrication were emphasized as the critical factors to the deployment effort.

Coordination & Collaboration

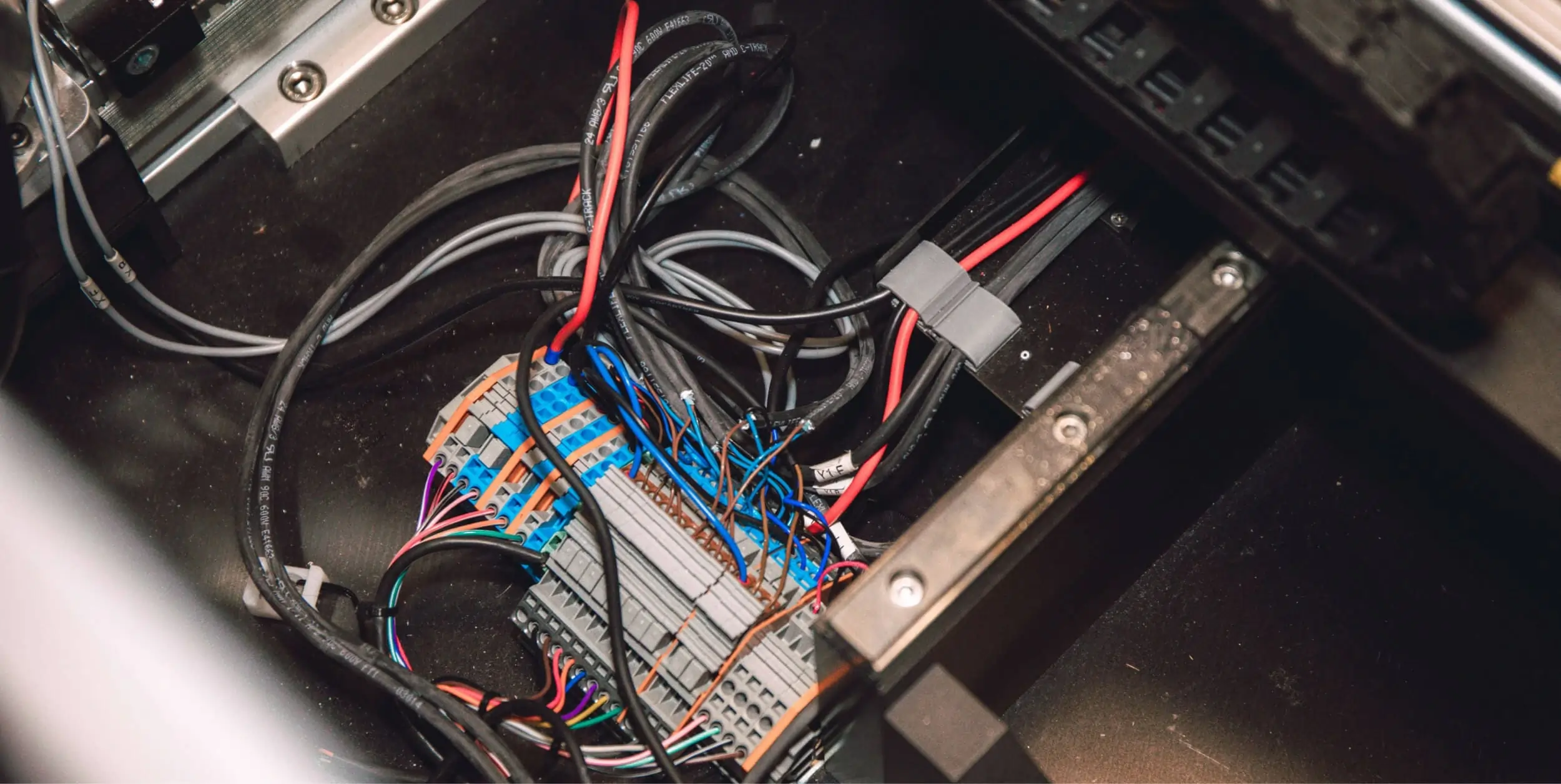

The delivery system consisted of approximately 20 individual components, 8 different vendors, 7 fabrication processes and a variety of materials: aluminum, sheet metal, injection molded plastic, custom cut adhesive, and CNC machined plastic. The goal was to ship over 5,000 systems, in four months, to retail stores throughout Canada and the US. This required coordination and collaboration within our extensive, trusted network of proven vendors. Working closely together, Sigma Design and Ziba Design ensured a seamless transition to manufacturing and deployment.

About the Accufit Digital Measuring System

By digitally measuring the relationship between your eyes, face and frame, LensCrafters’ professionals are more accurately able to place your prescription in your eyeglasses with 5x more precise measurements than manual methods.

Stores outfitted with LensCrafters’ new and exclusive AccuFit Digital System at each eyewear consultation area represents a major investment by the brand.