Blueberry Harvester Optimization

ZEISS Corona Process Vis/NIR Spectrometer + Custom Mount on Oxbo 7450 Blueberry Harvester

Objective

Challenge Accepted

- Withstand vibration and harsh conditions

- Avoid interfering with operator workflows

Solution Delivered

Result

“We came to Sigma Design with a unique challenge: integrate a sensitive ZEISS Corona spectrometer onto a moving conveyor onboard a working harvester. This equipment is used heavily, daily during harvest operations. The solution had to be rugged, safe, and installable without disrupting the pace of work or compromising operator safety. Sigma Design delivered exactly that.

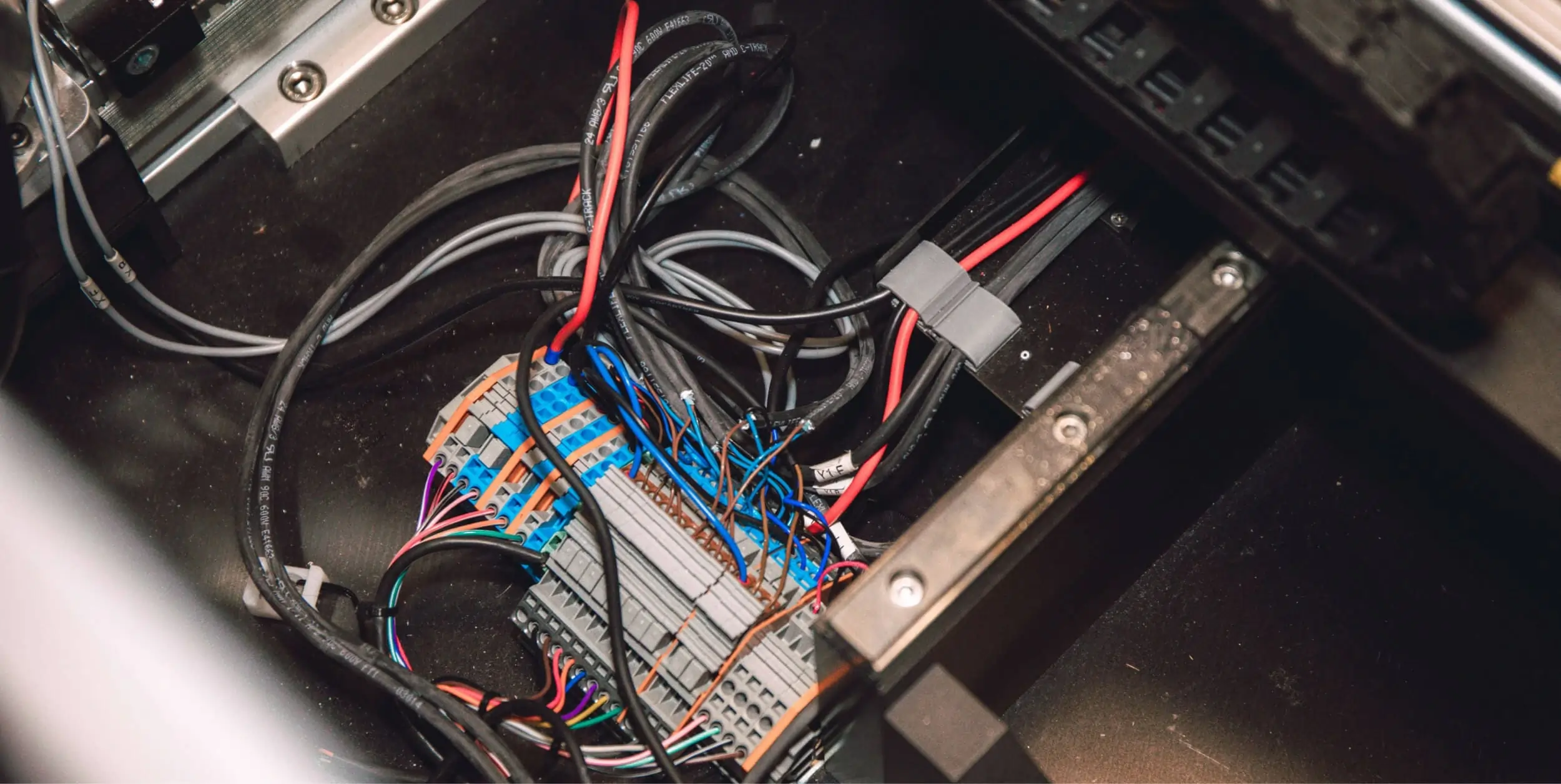

Their design-driven process produced a precision-fabricated mount system that not only secured the spectrometer and maintained alignment but also integrated a panel PC and full cable management all in a compact, field-ready form. It performed flawlessly under real harvest conditions.

What impressed us most was how Sigma Design balanced technical performance with human-centered design. The system didn’t just protect the optics—it improved workflow. The world of agriculture is rapidly becoming high tech, and it’s really great that Sigma has a design/fab outpost in Pendleton that is affordable and super responsive.”

— Jeff Lorton, Ag Optix