LAIKA Autoblaster

Transforming a prototype into a production-ready tool.

LAIKA, a feature film animation studio, came to Sigma Design with a CNC-controlled spray booth concept that had strong potential — but required some additional support to improve reliability, ergonomics and performance, optimized for their high precision workflow.

Challenge Accepted

Our team was asked to take this proof-of-concept and transform it into a system that was robust, safe, ergonomic, and production-ready. This meant addressing mechanical, electrical, usability, and manufacturing issues while ensuring the customer could scale confidently.

Solution

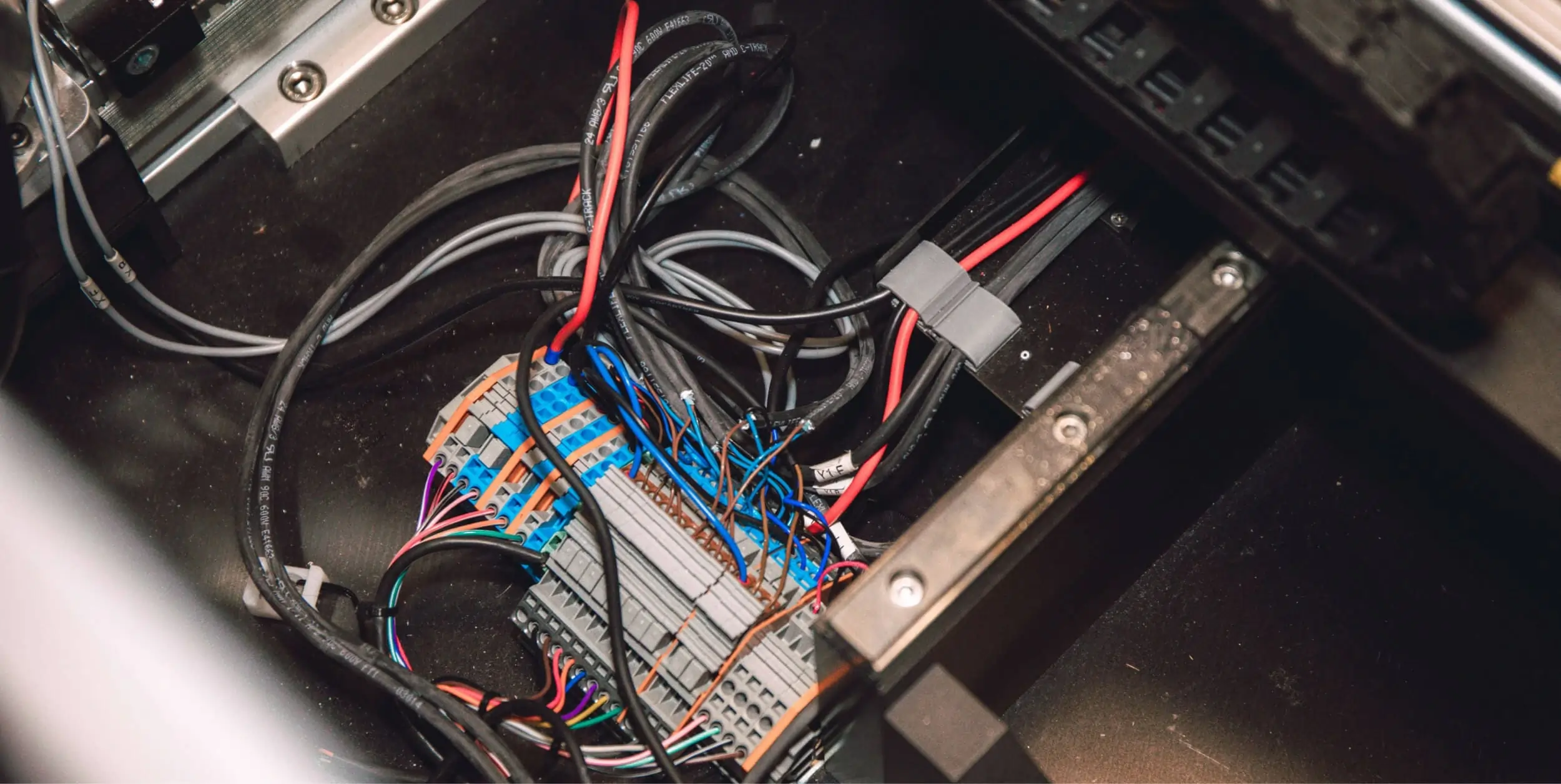

We redesigned the system - correcting wiring and electrical problems, redesigning the HMI for usability, adjusting the cabinet height for improved ergonomics, and significantly enhancing waterproofing, corrosion resistance, and overall reliability. We added a foot pedal to control manual spray functionality, automated the wiper controls, reduced overall weight for serviceability, made the system operable for both left- and right-handed users, and replaced key components with stainless steel for long-term durability. The control box was built to UL508a standards and throughout the project, the system was designed to facilitate scalable production.

After completing the first unit, the HMI controller became obsolete. Rather than ship with an unsupported HMI, we sourced a new controller, developed a replacement interface, and retrofitted the first unit to match the updated design for production.

Solution Details

Mechanical & Ergonomic Enhancements:

- Adjusted cabinet height for operator comfort

- Reduced system weight for easier service and mobility

- Added a foot pedal and automated wiper controls

- Enabled left- and right-handed operation

- Improved waterproofing

- Added corrosion resistance by using stainless steel components

Electrical & Controls Improvements:

- Corrected poor wiring and electrical design

- Redesigned HMI interface for clarity, reliability, and ease of use

- Laser-etched labels for durability and readability

- Designed and built to UL508a standards

System Compatibility:

- CNC-controlled spray booth with linear axis and rotational capability

- Supports both automatic and manual operation

LAIKA came to us with a prototype that had a solid concept. Sigma Design was able to bring the project across the finish line, and the customer now has a robust, scalable, and operator-friendly CNC spray booth that dramatically improves efficiency and throughput.

The redesigned system reduces personnel requirements, enhances ergonomics, increases reliability, and provides the consistency needed for high-volume production, turning their prototype into a dependable, production-ready asset.