Industrial Training International

From Early Prototype to Production

When Industrial Training International (ITI) approached Sigma Design, they had a big idea in an early form: Crane Operator Training Pods. These virtual training systems use a 400lb motion base and dual joystick controls to simulate crane movement with precision. While ITI had early prototypes, schematics, and third-party software, they needed additional resources to transform the concept into a manufacturable, scalable product. Initially, Sigma Design was tasked with building five motion base units and ten desktop training pods.

Challenge Accepted

The prototype Sigma Design received revealed deeper issues, which prevented the product from being built as designed: inaccurate CAD files, tolerance stack-ups, misaligned holes, and excessive component drift, all of which undermined performance and made units difficult to build with consistency. Prebuilt cables were expensive and unreliable for use with varying pod configurations.

Solution

For this small but complex product, Sigma Design’s multidisciplinary team provided:

- Electrical Engineering

- Software Engineering

- Mechanical Engineering

- Product Assembly

- Product Testing

- Production Expertise

- Inventory Control

- Packaging Design

Sigma Design brought together these in-house disciplines to improve the design and build a robust product that is reliable, easily maintained, contains more cost-effective components, and is easily adaptable to multiple crane configurations.

With our breadth of expertise, Sigma Design was also able to offer quality management, inventory control, and provide technical customer service to ITI’s customers.

This project was so successful that Sigma Design continues to manufacture for ITI and is also designing additional control boxes for various types of cranes on which operators can be trained.

Solution Details

In order to provide the most robust solution for ITI, Sigma Design utilized its multi-disciplinary team of engineers, fabricators and welders, assembly technicians, test technicians and logistics experts.

Mechanical Engineers led the product refinement, addressing alignment issues in the original CAD files by redesigning components for proper fit. They added service access points throughout the unit to simplify long-term maintenance. To ensure durability, the team performed force and failure analyses, confirming the product could handle rigorous training use. They also integrated foot pedals for improved user experience and designed a custom Pelican case to protect the pods during transport.

Sigma Design’s Electrical Engineering (EE) team optimized the system from the circuit level up. They refined the electrical schematics for clarity and function, and by utilizing their experience in strategic component selection, cut the cost of the custom PCBs by 50%.

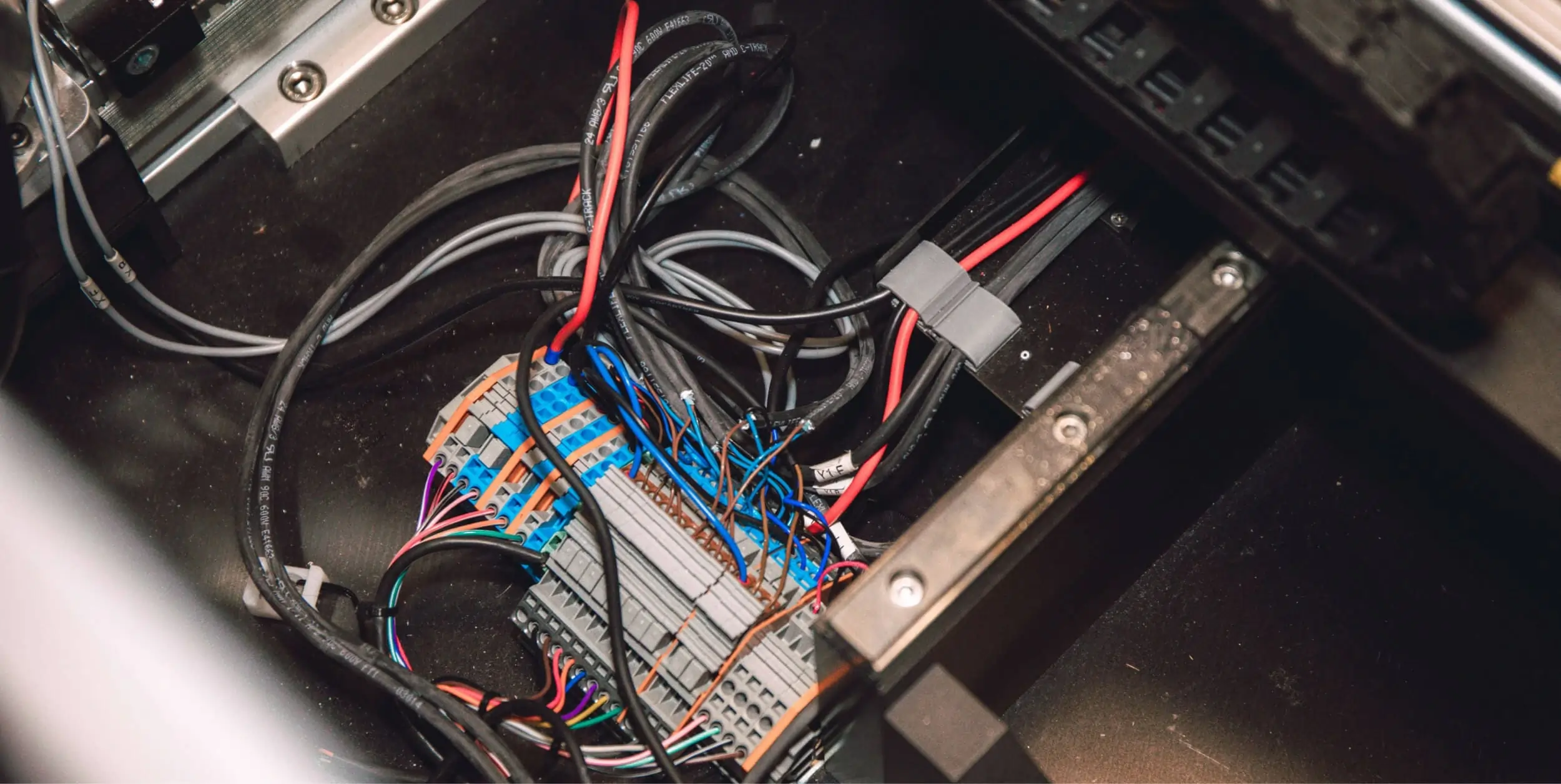

To simplify the system architecture, the EE team replaced a tangle of USB connections and excess wiring with an integrated power distribution system housed in the base of the pod - boosting both reliability and maintainability.

Sigma Design’s Production team collaborated with Engineering and Purchasing to source cost-effective, reliable components. Lab technicians implemented key updates to enhance durability. They repositioned LED base lights to avoid forklift damage and re-routed wiring harnesses to prevent pinching under the 400lb unit during operation.

These hands-on improvements helped reinforce the product’s resilience in real-world use. The team also handled final troubleshooting and fine-tuned the joystick controls for smooth, intuitive operation.

Result

ITI came to Sigma Design to build a prototype. What they got was a full-spectrum product development partner.

With our variety of capabilities under one roof, Sigma added value at every stage - turning a complex concept into a scalable, US manufactured solution.