Custom Battery Testing

Battery drain testing is a crucial process in evaluating the performance, reliability, and safety of batteries under controlled conditions. This case study highlights the methodology, safety measures, and insights gained from a comprehensive battery test.

Our customer needed to evaluate nine different battery types under accelerated conditions, simulating real-world and high temperature environments. The primary objective of this test was to assess performance consistency and ensure alignment with the manufacturer’s claimed specifications.

Custom Fixtures & Safety Protocols

-

- Thermal Chamber with Fire Suppression: To ensure safety, the battery testing was conducted in a thermal chamber equipped with an advanced fire suppression system. This system automatically detects overheating and deploys suppression agents, providing protection in the rare event of a thermal runaway scenario.

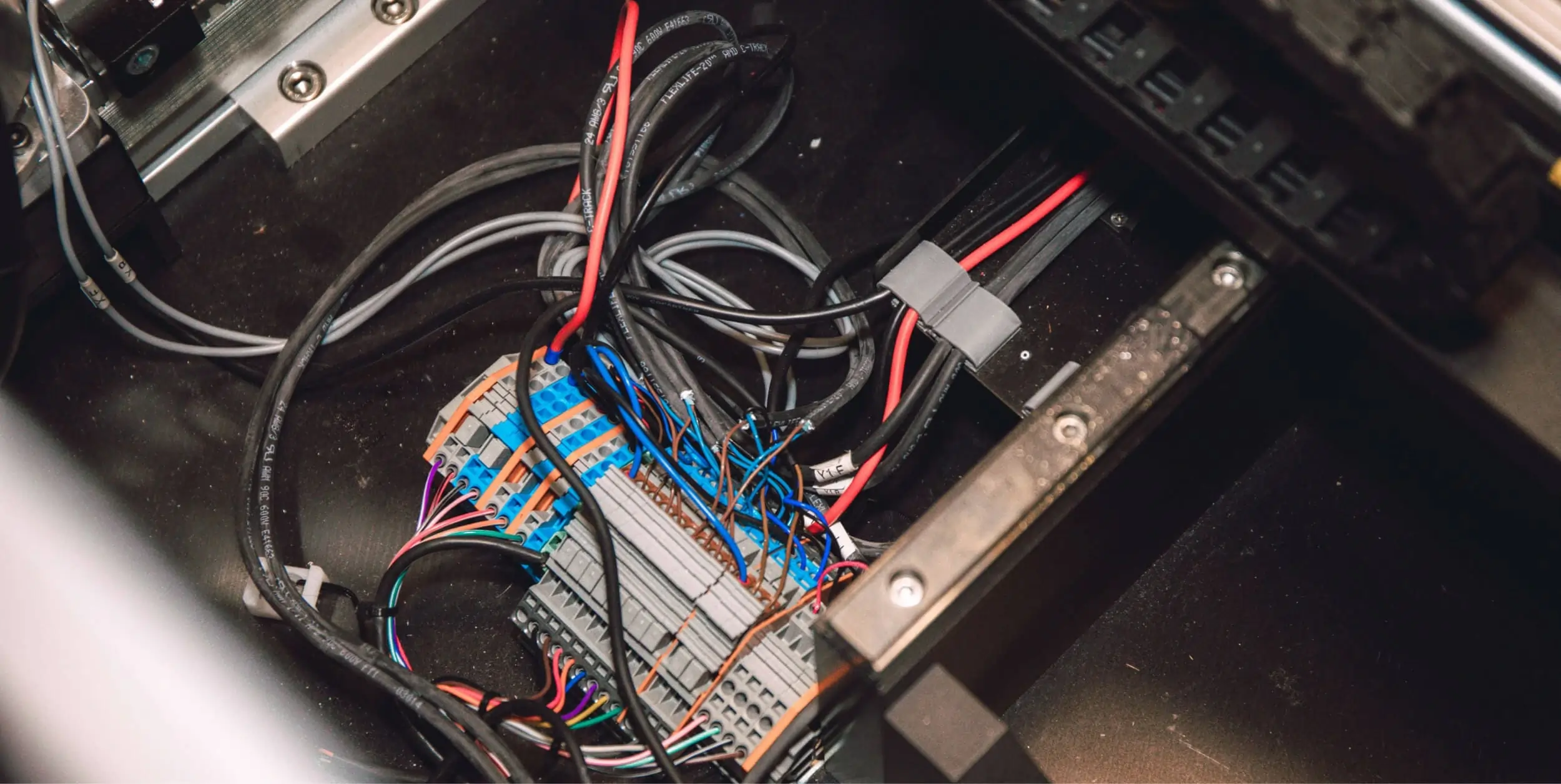

- Custom Battery Cradles: To accommodate the variety of battery types, the Test Lab engineered custom battery cradles and cabling solutions. These were designed to seamlessly integrate with the MACCOR battery testing system and fit within the thermal chamber.

Testing Environment

-

- Elevated Temperature Conditions: The temperature of the climate chamber was intentionally increased to accelerate chemical reactions within the batteries. This process speeds up the drain rate, allowing testers to observe potential failure points more quickly.

Customized Test Programs

-

- Tailored Variables: Each battery type underwent a unique test program, incorporating different discharge loads and cycling patterns. This allowed the team to evaluate how batteries respond under varying conditions.

Data Collection & Insights

Throughout the testing process, the team gathered extensive data, including:

- Voltage Drop: Measured to track the rate of power depletion.

- Capacity Loss: Monitored over time to assess the battery's ability to retain charge after repeated cycles.

- Efficiency Analysis: Evaluated to determine how effectively each battery type maintains its performance under stress.

Results

The battery drain testing conducted by the Sigma Design Test Lab team offers vital insights into battery performance under extreme conditions. By combining custom fixture development, thermal chamber operation, and multi-channel battery testing, Sigma Design delivered a comprehensive test solution. The system simulated realistic usage scenarios, provided detailed data for each battery profile, and gave our customer the confidence needed to make informed procurement decisions.

Contact us to learn more about our full suite of testing services.